Introduction

Previously, we looked at the benefits of automation in waste sorting technology. Let’s look at something a little more in-depth.

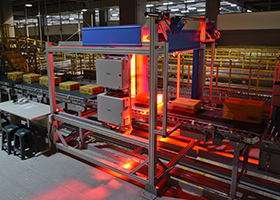

Smart Industrial Automation represents the next evolution in manufacturing and industrial processes. It leverages cutting-edge technologies such as the Industrial Internet of Things (IIoT), artificial intelligence (AI), and cloud computing to optimize production, enhance efficiency, and improve quality across various industries.

As part of the broader Industry 4.0 revolution, smart automation integrates intelligent systems, real-time data analytics, and machine learning to create highly adaptive and interconnected industrial environments. This shift is not just about replacing manual labor with machines but about enabling industries to operate with greater precision, agility, and sustainability.

The Foundations of Smart Industrial Automation

Key Concepts

- Industrial Internet of Things (IIoT) – A network of interconnected devices and sensors that collect and transmit data to optimize industrial operations.

- Artificial Intelligence (AI) – Machine learning algorithms and predictive analytics that enable automation systems to make informed decisions and improve over time.

- Cloud Computing – Remote data storage and processing capabilities that enhance accessibility and scalability for industrial applications.

- Machine Vision – Advanced imaging and optical technologies used for quality control and defect detection.

- Robotics and Autonomous Systems – AI-powered robots that enhance production efficiency and reduce human intervention in hazardous environments.

Industry 4.0 and Smart Automation

Industry 4.0 is characterized by the seamless integration of digital technologies into manufacturing and industrial operations. Smart automation serves as the backbone of this transformation, enabling businesses to shift from traditional mechanized systems to data-driven, intelligent workflows. This transition has been marked by a historical shift from manual labor to mechanization, followed by programmable automation and now, smart autonomous systems.

Benefits and Applications

Key Benefits

- Increased Efficiency – Automated systems streamline production processes, reducing downtime and waste.

- Improved Quality Control – AI-driven analytics and machine vision enhance product consistency and reduce defects.

- Enhanced Safety – Automation minimizes human exposure to hazardous environments, reducing workplace injuries.

- Sustainability – Smart automation optimizes resource usage, leading to reduced energy consumption and lower emissions.

Real-World Applications

- Manufacturing – AI-powered robots assemble complex components with precision, improving production speed and consistency.

- Automotive Industry – Automated inspection systems use machine vision to detect manufacturing defects in real time.

- Healthcare & Pharmaceuticals – Smart automation ensures accurate dosing in drug manufacturing and streamlines medical supply chain logistics.

- Energy Sector – IIoT-enabled sensors optimize power plant operations, reducing energy waste and improving grid management.

- Food & Beverage – Automated sorting and packaging systems enhance food safety and efficiency in processing plants.

Implementing Smart Industrial Automation

Key Steps in Implementation

- Assessment & Planning – Conduct a feasibility study to determine automation needs and define clear objectives.

- Technology Selection – Choose the right combination of AI, IIoT, robotics, and cloud computing to align with business goals.

- System Integration – Ensure seamless communication between existing infrastructure and new smart technologies.

- Data Management – Implement robust data collection and analytics systems for real-time decision-making.

- Workforce Training – Equip employees with the skills needed to operate and maintain smart automation systems.

Future Trends and Challenges

Emerging Trends

- AI-Driven Predictive Maintenance – Using AI algorithms to anticipate equipment failures before they occur.

- Edge Computing – Processing data closer to the source for faster decision-making and reduced reliance on cloud computing.

- Human-Robot Collaboration – Enhanced safety protocols and AI-driven interfaces that allow humans and robots to work side by side.

Challenges

- Cybersecurity Risks – Increased connectivity exposes systems to potential cyber threats.

- High Initial Costs – Investment in automation technology can be expensive, requiring long-term ROI strategies.

- Ethical Considerations – Concerns around job displacement and the need for reskilling the workforce.

Conclusion

Smart Industrial Automation is revolutionizing industries by enabling more efficient, safer, and sustainable operations. Businesses that embrace these technologies stand to gain significant competitive advantages. As automation continues to evolve, staying ahead of emerging trends and addressing potential challenges will be key to long-term success.

For companies looking to implement smart industrial automation, now is the time to invest in research, technology, and workforce development to ensure a seamless transition into the future of industrial automation.