Introduction

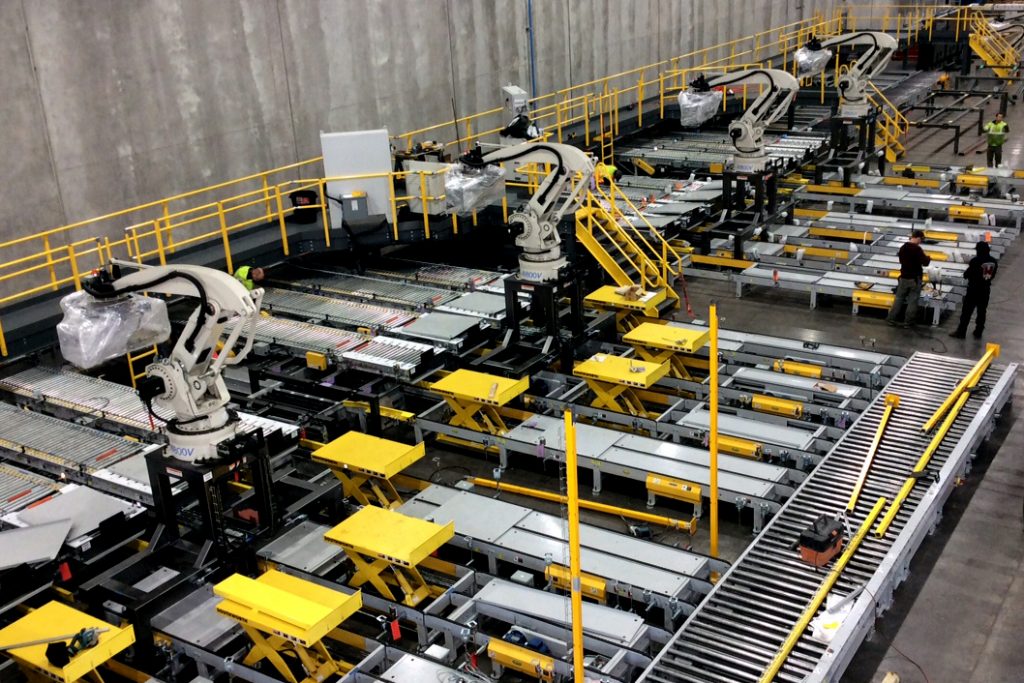

In today’s competitive manufacturing and logistics landscape, automation is no longer optional. Among the most critical components of automated material handling systems are palletizing robot arms, designed to stack, arrange, and transport goods with speed, consistency, and precision.

However, not all robotic arms are built the same. While generic robot arm makers offer flexible platforms suitable for a wide range of tasks, specialist palletizing robot arm manufacturers focus on purpose-built systems tailored to the unique demands of high-throughput palletizing environments.

In this article, we explore the fundamental differences between these two categories of robot arm suppliers, and why choosing a dedicated palletizing solution can deliver superior long-term results for warehousing, distribution, and production facilities.

Understanding Generic Robot Arms

Generic robot arms are designed for versatility. Typically supplied by large robotic brands, these arms feature programmable joints and interchangeable end effectors that allow them to perform a wide array of tasks—from welding and assembly to inspection and painting.

Key characteristics of generic robot arms:

- Multi-purpose applications

Designed to adapt to a broad range of tasks across industries. - Highly flexible programming

Users can write and modify complex routines for different operational needs. - Interchangeable tooling

Support for a variety of end effectors (grippers, suction cups, welders, etc.). - Generalised integration

Often require custom engineering and third-party solutions for specific tasks like palletizing.

While this versatility is valuable in environments that demand flexibility, it can become a limitation in high-speed, repetitive operations such as palletizing—where precision, cycle time, and throughput are mission-critical.

What Makes a Palletising Robot Arm Different?

Palletizing robot arms are developed by manufacturers who specialise in automated material handling. These systems are engineered specifically for stacking goods onto pallets, often at high speeds and in demanding logistics environments.

Core differentiators of palletizing robot arm manufacturers:

- Purpose-Built Design

These robots are mechanically optimised for vertical reach, long horizontal arm extension, and high payload capacities—perfect for stacking heavy cartons or large bags. - Optimised Motion Paths

The robot’s trajectory, acceleration profiles, and pick-and-place logic are finely tuned for high-efficiency palletizing patterns with minimal cycle times. - Integrated Software for Palletising Logic

Pre-programmed palletizing patterns, layer configurations, and automatic height adjustments make system setup faster and more intuitive. - Custom Gripper Options

Palletizing robot manufacturers provide end-of-arm tooling specifically designed to handle boxes, crates, or bags without product damage. - Enhanced Reliability & Support

Specialist manufacturers provide ongoing maintenance, spare parts, and system upgrades aligned with palletizing operations.

Why Specialisation Matters

When it comes to industrial automation, efficiency and reliability directly impact profitability. In high-throughput environments, a few seconds saved per pallet layer can add up to significant time and cost savings across shifts, weeks, and months.

Key advantages of choosing a specialist palletizing robot arm include:

- Faster Deployment: Reduced engineering and programming time due to built-in palletizing logic.

- Higher Uptime: Fewer integration errors and more robust mechanical design for 24/7 operations.

- Long-Term Cost Efficiency: Lower maintenance overhead and better performance over time.

- Scalability: Easier to scale with multi-line or multi-robot configurations purpose-built for material handling.

Conclusion

While generic robot arms offer flexibility across diverse applications, they often fall short in specialised, high-demand palletizing environments. Purpose-built palletizing robot arms – such as those developed by Okura – are engineered to deliver superior efficiency, reliability, and long-term value for businesses focused on logistics and high-volume production.

If you’re seeking to enhance your warehouse or manufacturing operation with a reliable, tailored palletizing solution, contact Okura Singapore today. Our team is ready to help you design and deploy a system that meets your exact requirements.