Introduction

As we previously discussed the robotic process automation industry, let’s take a look at how robot cobots can improve your operation.

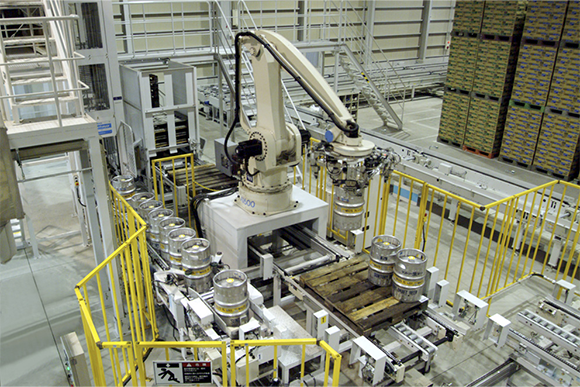

In today’s fast-paced manufacturing landscape, efficiency, accuracy, and automation play a crucial role in maintaining a competitive edge. Robotic palletizing, the process of using robots to stack and organize products on pallets, has become an essential solution for businesses looking to optimize their operations.

Collaborative robots (cobots) are transforming the palletizing industry by offering flexible, user-friendly, and space-efficient solutions. Unlike traditional industrial robots, cobots work alongside human employees, improving productivity without compromising safety. This guide will explore why cobots are an ideal choice for palletizing, the various solutions they offer, real-world applications, and how businesses can get started with cobot-based palletizing.

Why Choose Cobots for Palletizing?

Cobots offer a range of benefits that make them an excellent choice for palletizing applications. Here’s why businesses are increasingly adopting cobot solutions:

- Flexibility

Cobots are designed to handle a variety of product types, sizes, and pallet patterns. Whether stacking boxes, bags, or irregularly shaped items, cobot palletizing solutions can be easily adapted to different needs. Their lightweight design and modular programming allow for seamless redeployment across different production lines. - Safety

Unlike traditional industrial robots, cobots are equipped with built-in safety features such as force-sensing technology and collision detection. This allows them to operate safely in environments where humans are present, reducing the need for extensive safety barriers and enabling true human-robot collaboration. - Ease of Use

One of the biggest advantages of cobots is their user-friendly programming. Many models feature intuitive interfaces and drag-and-drop programming, eliminating the need for extensive coding knowledge. This makes it easier for companies to deploy and modify their palletizing setups with minimal training. - Fast ROI

Automation with cobots leads to increased efficiency, reduced labor costs, and fewer errors, all contributing to a faster return on investment (ROI). Many businesses experience ROI in under a year due to improved throughput and reduced operational expenses. - Space-Saving Design

Unlike bulky industrial robots, cobots have a compact footprint, making them ideal for facilities with limited floor space. Their ability to be mounted in various orientations, including on tables, ceilings, or walls, further enhances their space efficiency.

Cobot Palletizing Solutions

Cobot Model Overview

Different cobot manufacturers offer models with varying payload capacities to accommodate a range of palletizing needs. Common payload options include:

- Light-Duty Cobots (up to 12 kg) – Suitable for handling lightweight packages and boxes.

- Medium-Duty Cobots (12-16 kg) – Ideal for standard palletizing applications in industries like food, pharmaceuticals, and logistics.

- Heavy-Duty Cobots (16-25 kg) – Designed for high-capacity palletizing and heavier loads.

Gripper Options

The effectiveness of a palletizing system depends on the type of gripper used. Some common gripper options include:

- Vacuum Grippers – Ideal for lightweight boxes, bags, and flat surfaces.

- Finger Grippers – Suitable for handling irregularly shaped products.

- Magnetic Grippers – Used for metal objects.

Software and Accessories

Cobot palletizing solutions can be enhanced with specialized software and accessories, such as:

- Pre-Configured Software Packages – Simplify palletizing programming and integration.

- Vision Systems – Cameras and AI-driven recognition for accurate product placement.

- Conveyor Tracking – Synchronization with conveyor belts to automate product handling.

Applications and Case Studies

Industry Examples

Cobot palletizing solutions are used across multiple industries, including:

- Food & Beverage – Automating palletizing of packaged goods, reducing manual labor.

- Pharmaceuticals – Ensuring accurate and contamination-free stacking of medical products.

- Logistics & Warehousing – Improving efficiency in order fulfillment and shipment preparation.

Getting Started with Cobot Palletizing

- Finding System Integrators

To ensure a smooth implementation, businesses should work with qualified system integrators who can customize the solution to meet specific requirements. - Conducting a Proof of Concept

Before full-scale deployment, it’s advisable to start with a small-scale proof of concept to evaluate feasibility, optimize workflows, and address any potential challenges. - Utilizing Resources

Businesses can explore various resources from cobot manufacturers and automation solution providers, including:- Official Websites – Comprehensive product information and case studies.

- White Papers & Technical Guides – Detailed insights into robotic palletizing.

- Software & Accessory Marketplaces – Platforms offering compatible software and hardware solutions.

Conclusion

Cobot palletizing solutions provide businesses with a flexible, safe, and cost-effective automation option. By reducing manual labor, improving efficiency, and ensuring adaptability, cobots deliver a strong return on investment while optimizing industrial automation.